inotec solutions for stock identification in warehouse logistics

Single location labels in high-bay warehouses

The basic equipment for all high-bay warehouses: Different colour identification per racking level. Barcodes printed on white background, surrounded by coloured sections. Compatible with voice-picking systems and inotec single and multi-level labels.

Multilevel labels - the inotec solution for warehouse racking and shelves

The multi-level label combines the barcodes for all levels of a high-bay warehouse in one label. The unique design with the angled barcodes ensures absolute process reliability. Accidental scanning of the wrong storage location is eliminated.

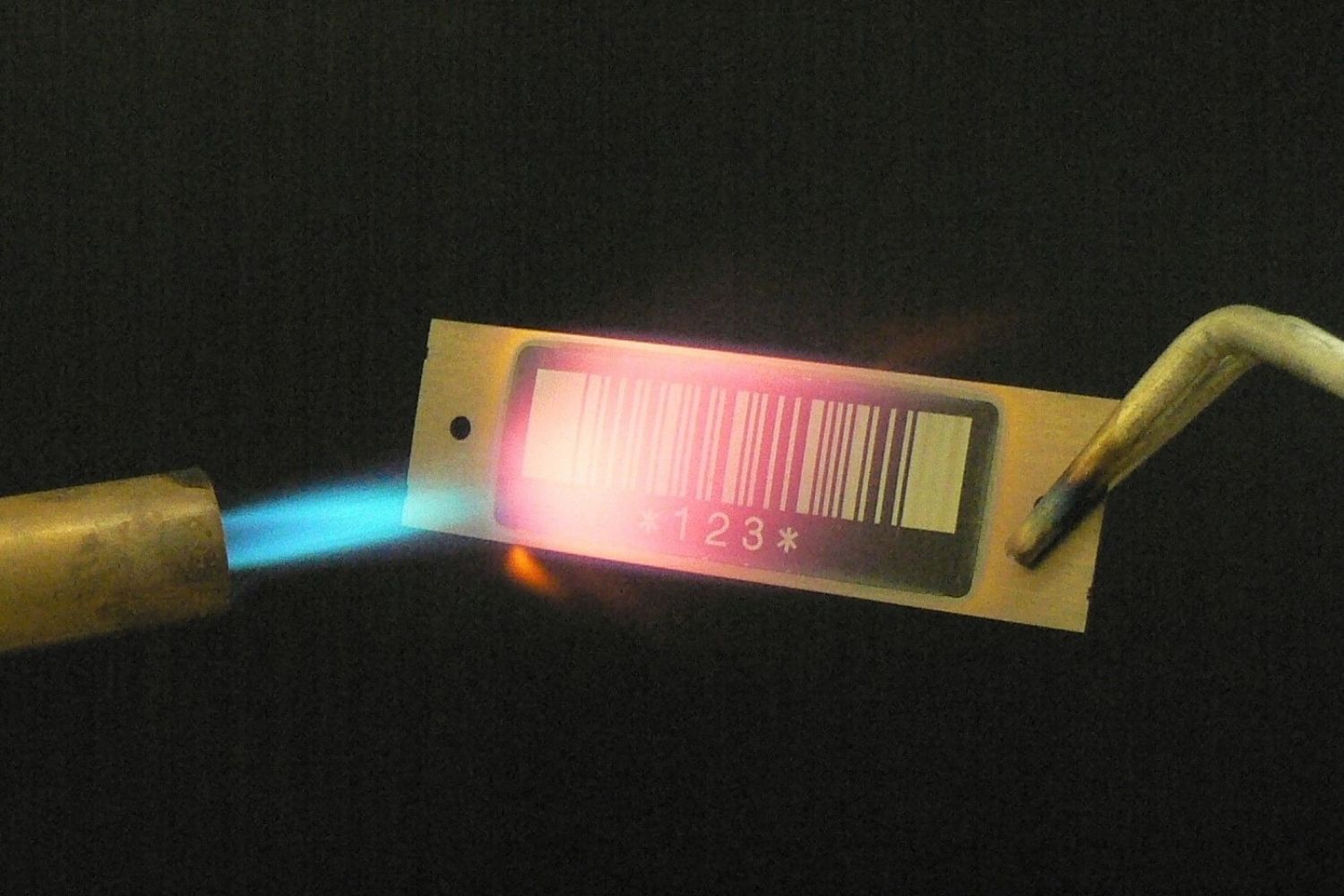

Retroreflective labels - the alternative to floor marking

Retroreflective labels enable secure and precise scanning of barcodes even from a distance (e.g. for high-bay or block storage locations). The alternative to floor marking.

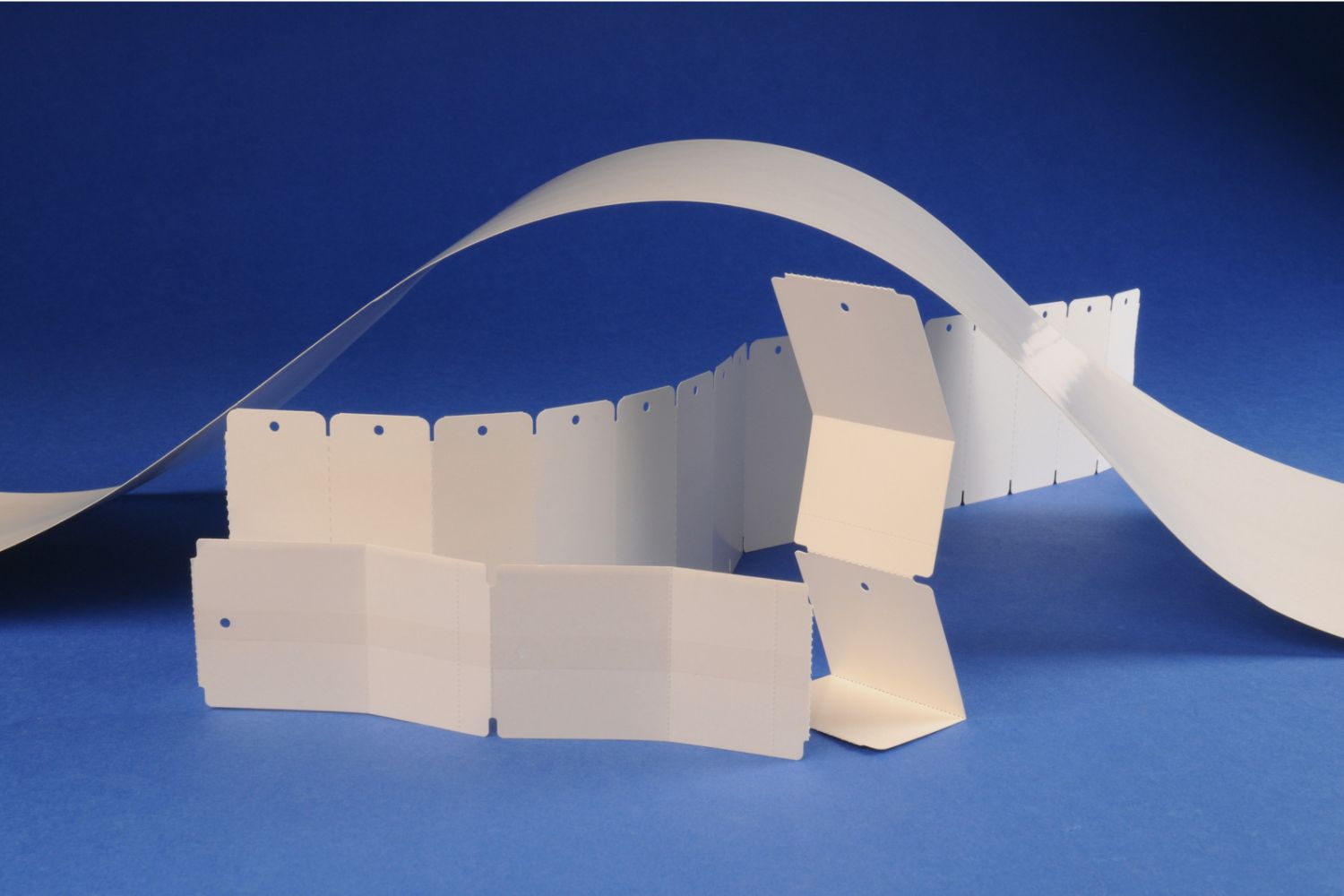

Cantilever Racking Identification in the warehouse

When storing pipes, metal parts and wood of different lengths, it may often be necessary to shorten or lengthen cantilevers. With screw mountable and robust, metal label holders from inotec, you can use flexible barcode markers for your storage locations.

Individual solutions for floor marking in block storage

Floor marking solutions from inotec can be placed almost anywhere and always look good. They are versatile and so flexible that they always meet your requirements, and additionally they can contribute to safety. Available in a number of practical versions - depending on what you need.

Block storage signs

Identification for high-bay or block storage. Retroreflective barcode for reading up to 12m height. Angled signs for precise legibility!

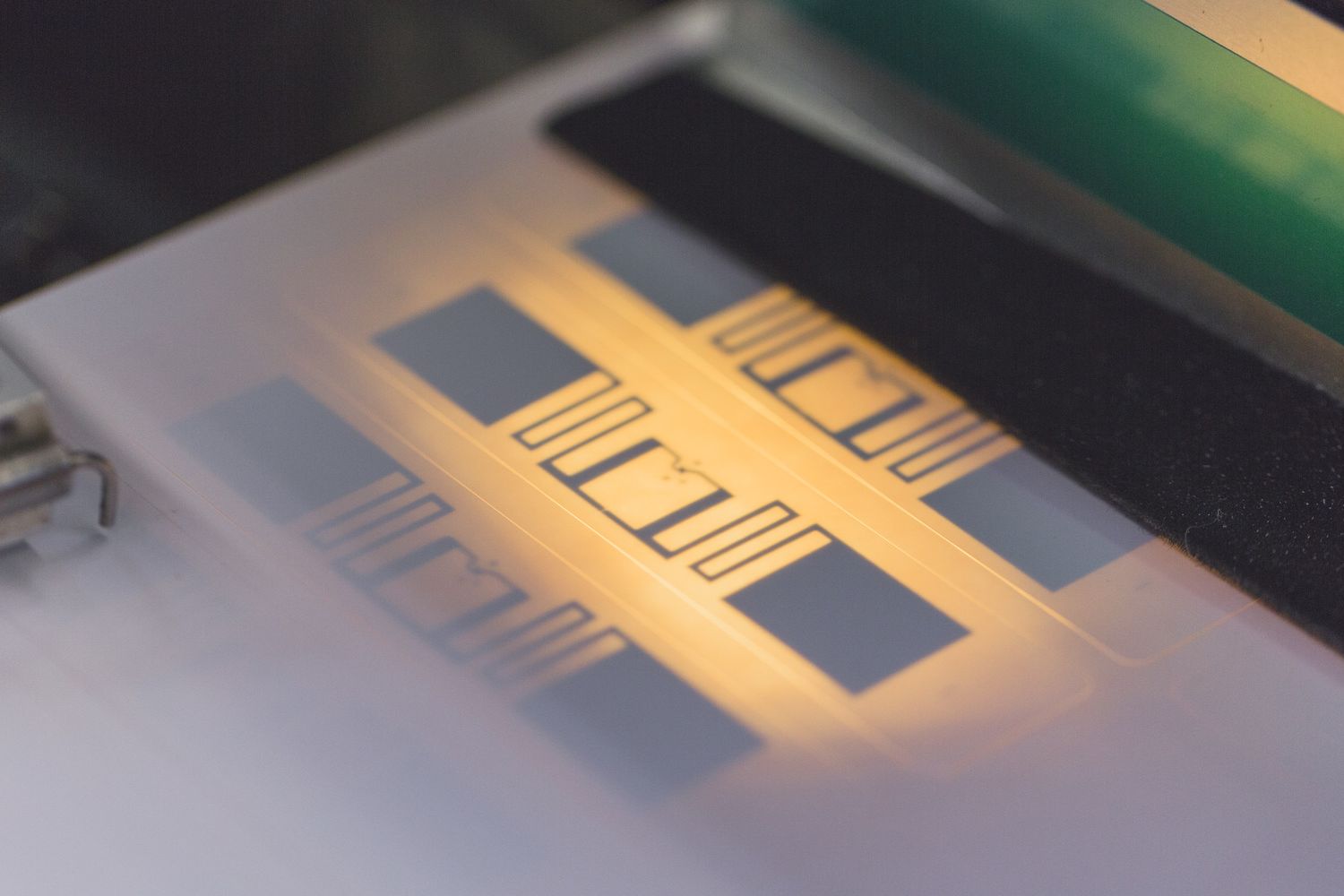

3. Marking of open fronted storage bins in miniload systems with inotec barcode labels

Marking of shelf systems for an automatic small parts warehouse (AKL)

Adhesive labels for open fronted storage bins

Labels produced by digital printing or thermal transfer. Classical barcode labels for marking the storage bins in the automatic small parts warehouse (AKL).

Magnetic labels for open fronted storage bins

The ideal solution for deep-freeze warehouses. Fast and efficient identification with unlimited design possibilities.

Scanner rails (label holders) for the automatic small parts warehouse (AKL)

Transparent plastic label holders to protect the barcode labels, flexible and non-rubberized.

Intelligent ground marking solutions

Floor marking solutions from inotec can be placed almost everywhere and always look good. They are versatile and so flexible that they always fit and can additionally contribute to safety. Available in a number of practical versions - depending on what you need.

Warehouse line marking

Colour markings can be applied directly to the warehouse floor. Walkways, picking lanes, even pictograms or zone marking of security areas and block storage areas.

Drive through racking bays in a high-bay warehouse

For fork lift trucks. Extremely robust adhesive labels with highly visible markings, for quick identification of pallet positions.