Durable RFID solutions for maximum security

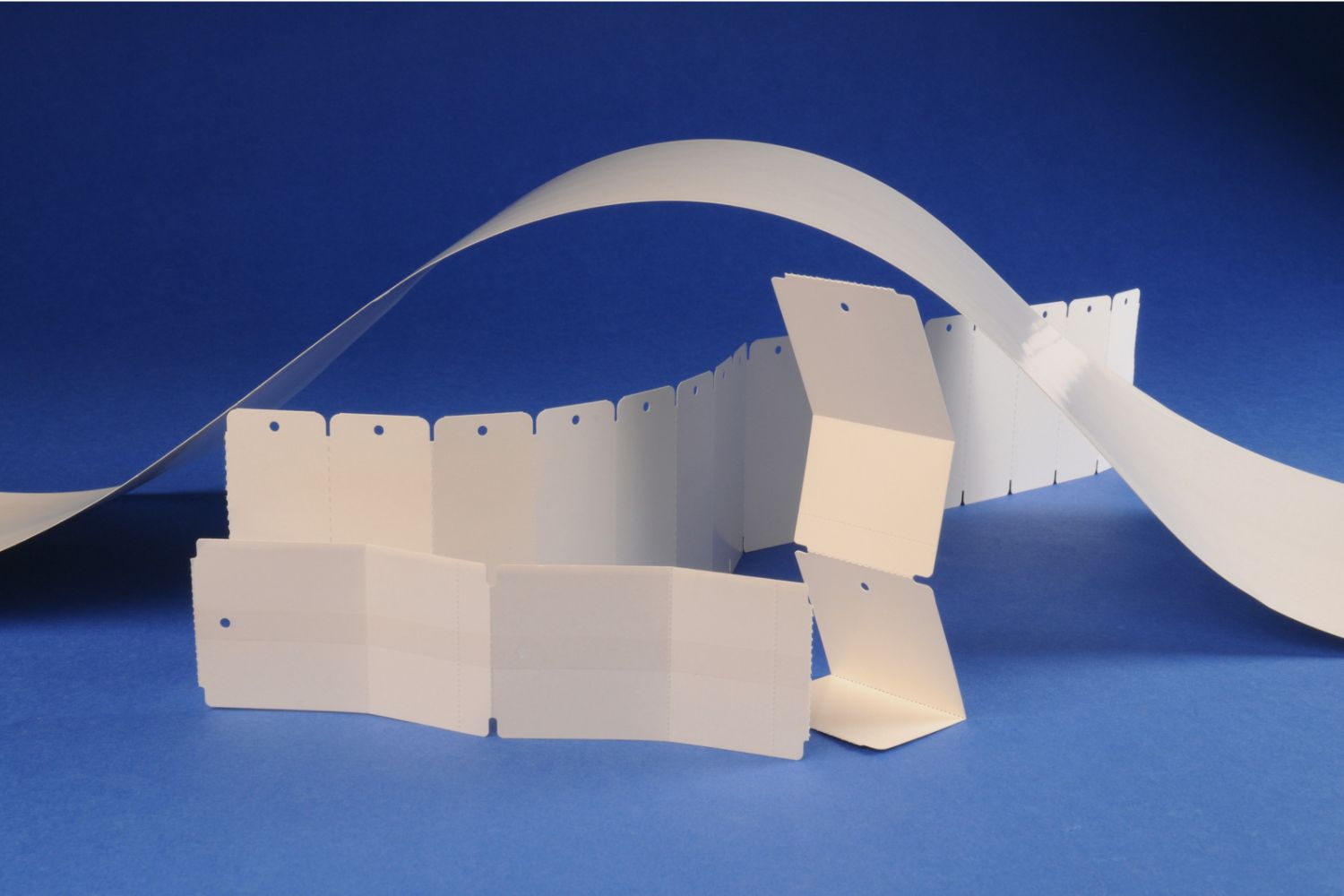

inotec RFID inmould solutions are perfect when it comes to the permanent marking of (reusable) plastic pallets, containers and trays. They are resistant to wear, UV light, cleaning products, weak acids and other chemicals.

Fixed and absolutely hygienic

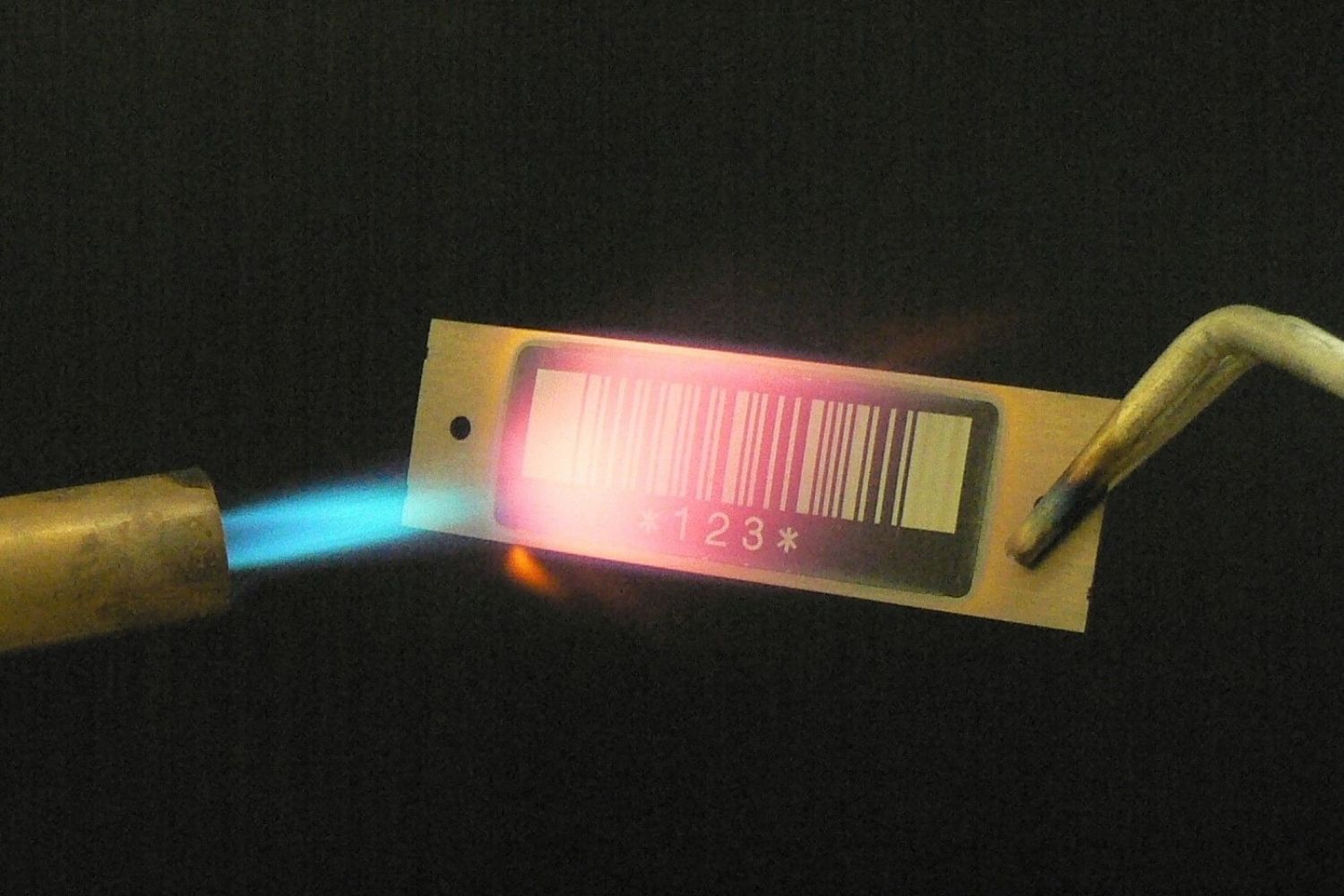

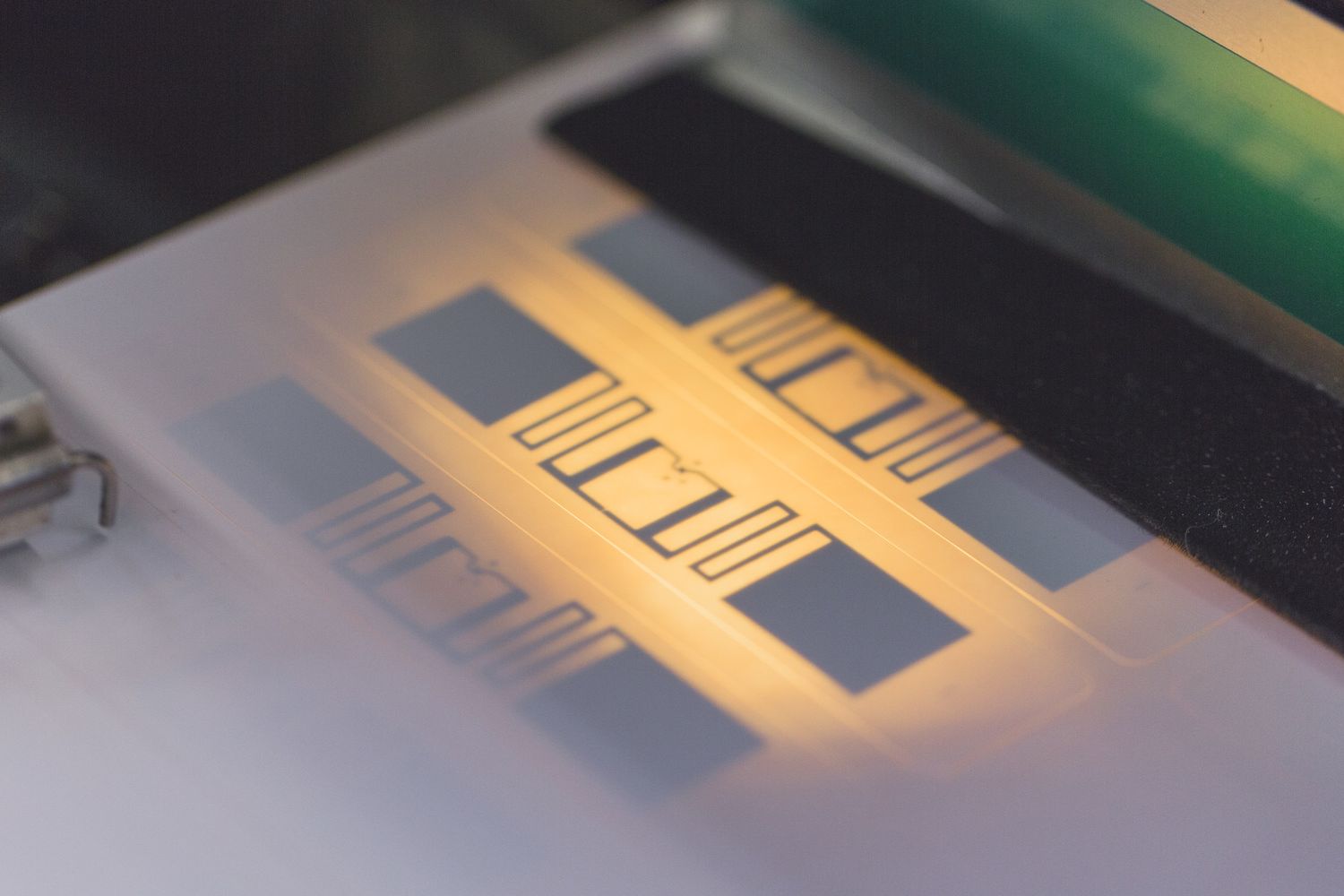

The single-layer label with integrated barcode, printed RFID antenna and mounted RFID chip is inseparably connected to the load carrier by injection moulding. This makes the RFID tag an integral part of the load carrier and absolutely tamper-proof. This means that the high hygiene requirements of the food and pharmaceutical industries are no longer a problem. It is not without reason that inotec is the only company in the industry to be GS1-certified for the production and delivery of inmould labels for meat container labelling.

inotec RFID inmould solutions are always manufactured according to requirements. From research, production and installation to training and long-term service.

Always individual. Always inotec. Always safe!

The inotec Inmould Advantage

- Ideal for returnable transport containers and plastic pallets

- Various chips such as Impinj Monza 5 or NXP G2iM possible

- Suitable for PE, PP, ABS, PS, Nylon and Polycarbonate

- The only company GS1 certified

- UHF frequency ranges from 860 - 960 MHz

- Permanent bond - no stripping possible

- Short production time and low cost

- High resolution digital printing